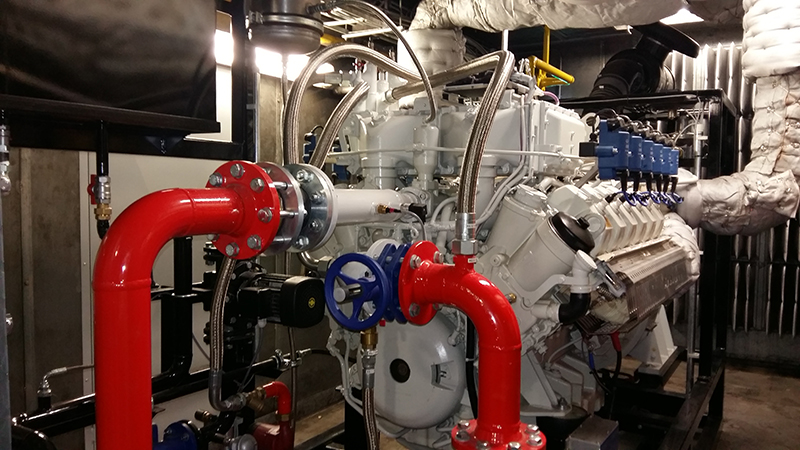

Driven by gas engines

To operate independently of the electricity grid, Verheust supplies two 12-cylinder gas engines, each with 450 KW, which operate on standard natural gas. The second gas engine will only start up once the first one is fully loaded. The intention is to run both at full load for maximum efficiency. The gas engines are then connected to two Siemens generators. The thermal heat from the gas engines will eventually be used to increase the calorific value of some of the recycling products through drying.

Stabilisation of consumption

Short-term peaks in consumption, which cannot be supplied by the gas engines, can be absorbed by using Supercaps. This allows the gas engines to run at lower power, which increases their efficiency and service life. Net stabilisation is completed with Li-ion batteries and associated BMS to accommodate any prolonged power surges along with the Supercaps.

The complete power supply will be assembled in three containers that will be placed on customer premises. These are currently in full production; the power supply should be operational as from June and the site can run in an ecological and cheaper way than at present!